Referenzen

Roof panels for the Flexity tram in Palermo, Italy

What looks like a three-dimensional, single-cast component on the sides of trams from the Flexity range from Bombardier, consists of pultruded GRP elements with glued-on end caps, which have been milled, glued, primed and painted. Optionally, the 656 mm wide roof panel can also be manufactured with a glued-on bracket. It has fire protection in accordance with NF F 16-101 and DIN 5510. For new projects, we also meet fire protection requirements in accordance with EN 45545.

Spoiler for the M5000 tram in Manchester, UK

Bombardier designed the M5000 tram as a high-floor tram specially for use in Manchester. The spoiler consists of a solid stainless steel frame with a glued-on GRP profile. The profile was milled on modern CNC machines at TC, glued to the frame, primed and painted with a special 2K-PUR metallic paint. It is manufactured in different lengths and designs. It has fire protection in accordance with BS 6853. For new projects, we meet fire protection requirements in accordance with EN 45545.

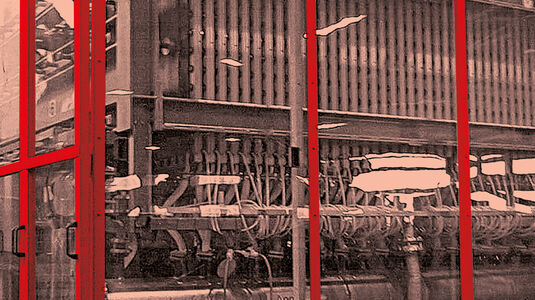

Interior deck system for the Rhein-Ruhr Express (RRX)

The high-capacity, double-decker local trains developed by Siemens are fitted with an interior deck system from TC. All of the components – middle deck, low-floor and high-floor haunches, inner side deck and cold air duct – are based on GRP pultruded profiles.

Airflow system for the Desiro ML/ÖBB, Austria

Having developed and manufactured the airflow system for the Desiro ML Mittelrheinbahn and the Desiro ML Brussels, TC is now also producing the airflow system for the Desiro ÖBB. The respective systems are based on pultruded profiles made of fibre glass-reinforced plastic. For the air ducting system, the fire protection properties of the GRP profiles were set in such a way as to meet the requirements in accordance with EN 45545.

Roof panels for the Sprinter Lighttrain in the Netherlands

For the Sprinter Lighttrain made by Bombardier, stainless steel sliding blocks were glued into the GRP profiles (A2 bonding) for high rigidity. Vertical tear resistance of 2,772 N was required for every single adhesive bond. This requirement was far surpassed in practice.

The roof panel, which has the appearance of a 3-dimensional component from a single cast, consists of pultruded GRP profiles and 3D moulded parts, partly combined with stainless steel components. 3D-printed components may also be used.

Side panel casing components for the TALENT local train

TC supplied side panel casing components for the TALENT local train, manufactured by Bombardier Transportation in Talbot. These components were manufactured on the basis of nine different pultruded profiles. All of the components – the GRP profiles and other components made of SMC pressed parts, EPDM covers, stainless steel and aluminium components – were designed, machined and bonded together at TC. This meant that the customer was supplied with ready-to-paint finished parts.

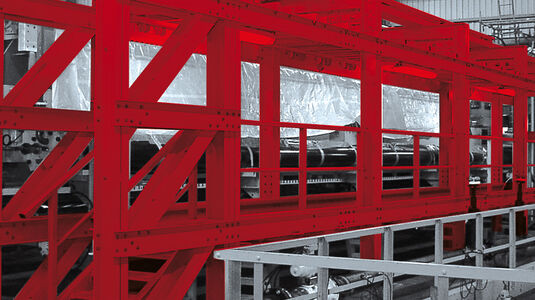

Air flow system for the Rhein-Ruhr Express (RRX)

The various systems are based on pultruded profiles made of glass fibre-reinforced plastic produced by Exel Composites in Belgium. For the air ducting system, the fire protection properties of the GRP profiles were set in such a way as to meet the requirements in accordance with EN 45545.

Interior deck system for the Desiro ML

Following the development of the interior deck system for the Desiro ML Mittelrheinbahn and the Desiro ML Brüssel at TC and its subsequent delivery, the interior deck system for the Desiro ÖBB is now being manufactured at TC. The various systems are based on pultruded profiles made of glass fibre-reinforced plastic produced by Exel Composites in Belgium.

External casing components for urban buses and longdistance coaches

For many years, we have been developing casing components for the exterior of buses and railway vehicles here at TC. One advantage of GRP profiles is that we can produce different component lengths based on just one tool. This increases flexibility in design. The components are based on a profile made of glass fibre-reinforced plastic, which we process in our CNC-controlled milling machines to produce

precision-cut parts for e.g. wheel arches, indicators and maintenance covers. We can also install reinforcements or add-on parts at the same time if required.

Repair side walls for urban and overland buses

The side walls of urban and overland buses are put under major strain by the day-to-day demands placed on them: stone chipping, scratches and minor and major accidents quickly cause damage to the thin-walled metal sheets found in older models. What's more, in some cases the effects of weather and chemicals such as de-icing salts and cleaning products can lead to unsightly signs of corrosion, which can damage the image of the bus company among its customers. This makes repairs and touch-ups necessary.

As non-corrosive plating is not always available for older vehicles, TC manufactures side walls made of glass fibre-reinforced plastic that are suitable for all such models and makes, and provide an optimal and durable alternative to older metallic plating.

GRP ladders

Within the chemical industry, systems can only seldom be optimised using off-the-shelf solutions. Generally speaking, all TC structures are developed in accordance with DIN EN ISO 14122. Certification according to DIN EN ISO 9001:2015 confirms the excellence of our quality management. The pultruded GRP construction profiles from Exel Composites comply with EN 13706/E23. We advise you on site and can accommodate your wishes in terms of corrosion-resistant access systems. We provide design, manufacture and assembly on site, all from a single source.

5-door housing

A 5-door GRP housing for a pastillation belt was designed and built here. Its surfaces are easy to clean and all of the system components are easily accessible via the many doors.

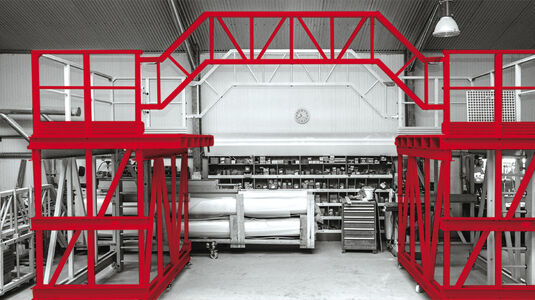

Electric crane platform

GRP designs meet requirements for high mechanical stability and are also resistant to many chemicals and corrosion. They do not conduct electricity and are easy to assemble. We are always delighted to work on special projects for our customers. The task here was to design a special GRP crane platform with a stainless steel crane unit. This was developed and built by TC and is used to raise battery packs by approx. 1 m. The complete crane platform can be rolled manually to the respective place of use.

Mobile platforms

We can create mobile platforms on request. Discuss your mobile platform requirements with us. For mobile platforms we generally use GRP construction profiles manufactured in accordance with EN 13706 / E23. This ensures that the platform has a minimum load-bearing capacity. These GRP construction profiles typically have an isopolyester resin matrix. For structures that are exposed to higher chemical stress, we can also use profiles with a vinyl ester resin matrix. If profiles need to be connected with angle brackets, we generally use V4A stainless steel connectors. We do not use short GRP remnants for such connections because they are not sturdy enough.

Railings

GRP railings meet requirements for high mechanical stability and are also resistant to many chemicals and corrosion. They do not conduct electricity and are easy to assemble. Our GRP railings meet the requirements of DIN EN ISO 14122. We can provide testable static analysis for your GRP railings from an independent engineering firm. If your GRP railings require a more complicated design, we can also provide a finite element calculation to verify their operational capability.

Cover for a salt spray test facility

The original plexiglass cover of this salt spray test system needed to be replaced by a new, much sturdier cover. This was designed and manufactured by TC on the basis of GRP profiles and GRP sheet material.

Spray and touch protection

We have already designed and built an array of different spray protection systems for indoor and outdoor use at industrial plants on behalf of our customers. These traditionally consist of a load-bearing system made of weather-resistant GRP profiles and transparent, weather-resistant plastic panels. The spray protection system has already been enhanced with e.g. fastener frames for electric distributors, pipe supports, GRP cable bushing systems, GRP doors and ports and special openings for sample extraction. As the GRP spray protection systems for outdoor use are also exposed to high wind loads, we are happy to provide auditable static analysis from an independent structural engineering firm to confirm their stability.

Stairway

The handrail of your GRP stairway won’t ever feel really cold to the touch, even in winter, thanks to the low thermal conductivity of the pultruded GRP profiles. Generally speaking, all TC structures are developed in accordance with DIN EN ISO 14122. Certification according to DIN EN ISO 9001:2015 confirms that our quality management is sound. Pultruded GRP construction profiles produced by Exel Composites meet the requirements of EN 13706/E23.

GRP profiles for energy efficiency in the constructions industry

Global climate change and the necessary decline in the dependence on fossil fuels lead directly to better insulation for all types of buildings. The energy footprint of buildings is greatly affected by its windows and doors. Conventional materials such as steel, aluminium, PVC and wood only meet requirements for energy efficiency, durability, robustness, cost-effectiveness and low maintenance to a certain extent. By contrast, pultruded composite profiles can absorb high mechanical loads while also meeting insulation requirements.

Façade elements for the Deichman Library in Oslo

The new Deichman Main Library, which opened in 2020, stands right beside the Norwegian Opera House in Oslo. Now complete, the library is a paragon of energy efficiency and low greenhouse gas emissions. We are delighted to have contributed towards the success of this project. Some of the extra-large, solid window frontage profiles on the six-storey building were manufactured using modern machinery at Techno-Composites Domine GmbH. At approx. 0.5 metres thick and featuring several hollow chambers, these façade element profiles are clearly visible on the building.

Roller shutter housing connector

We worked with a customer from the construction sector to develop a GRP connecting element that optimally connects the window frame and window blind box. This transfers the high mechanical loads exerted by wind in an optimal way. At the same time, the GRP profile improves the insulation capability of the entire system. The GRP profiles are drilled and counterbored on a large scale using a CNC machine, thus making installation significantly easier for the workmen.

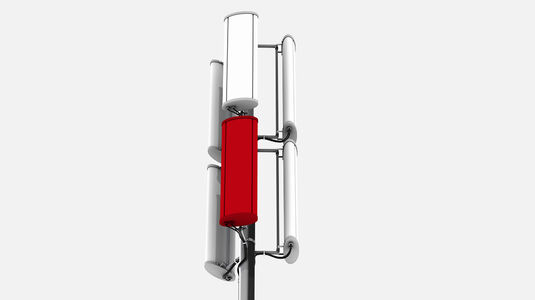

Mobile telecommunications

Glass fibre-reinforced plastics are ideal for use in the field of mobile communications.

They are

Mobile stairs

Do you need safe and corrosion-resistant access systems for your operations? And do these stairs also need to be movable?

Then get in touch.

We can design and manufacture special solutions as oneoff commissions or small batches, or a standard solution in larger quantities. Made of glass fibre-reinforced plastic profiles, our mobile stairs are suitable for using in corrosive environments or for sites where a stairway needs to have an electrically insulating effect.

Walkways and platforms

GRP walkways and platforms can be individually adapted to your needs in terms of length, width, support distance, etc. It is also possible to absorb higher loads, which can be taken into account in the design phase. Generally speaking, all TC structures are developed in accordance with DIN EN ISO 14122. Pultruded GRP construction profiles produced by Exel Composites meet the requirements of EN 13706/E23. Profiles with an iso-polyester resin mix are typically used. Vinyl ester resin profiles are also available if higher chemical resistance is required.

Corner and plug-in profiles and seat support covers

TC products aren’t always apparent at first glance. They often resolve problems in complex assemblies. For instance, they are used to meet the need for a component that has good thermal insulation properties, but is also lightweight and has a high mechanical load capacity.

Providing solutions with composite materials:

0 to 100 km/h in 2.9 seconds – thanks to carbon

Carbon is a composite material and differs significantly from quasi-isotropic materials like steel or aluminium. As with glass fibre-reinforced plastics, the material properties depend on the direction. With a density of approx. 1.6 g/cm³, the material is very light, while maintaining good rigidity and vibration behaviour. If you want to increase the rigidity of a GRP component, it is often sufficient to use a blend of glass and carbon fibres.

Roof rim for trams in Karlsruhe

When manufacturing and attaching the roof rim for trams in Karlsruhe, it was particularly important to ensure that the adhesive bond was secure. These dual-system vehicles, which are manufactured by Bombardier, can reach speeds of up to 100 km/h. The GRP roof rim was attached to the vehicle body using an invisible aluminium bracket. The adhesive bonds between the aluminium and GRP were applied in accordance with DIN 6701, Class A1, and thoroughly tested in conjunction with the Fraunhofer Institut. FEM calculations demonstrate the permanent durability ofthe adhesive bond.

Door supports for the ICE 4

The ICE 4, which was jointly developed by Siemens and Bombardier, is fitted with GRP door supports from TC. The door supports are installed immediately above the sliding doors. The 14 different types of door support are based on a GRP pultruded profile. The door support is a highly complex component which TC has once again been about to demonstrate its performance as a systems supplier. It consists of different aluminium profiles, brackets for the power supply and emergency brake, and infrared sensors. In addition, many door supports are fitted with a lockable flap and toilet ‘occupied’ displays. All of the adhesive bonds on the door support meet the requirements of DIN 6701. The entire door support is painted in two colours.

Oscillating frame structure

In this project, TC created an oscillating, suspended double frame structure with hollow chambers for holding electrical components for a customer. The entire frame structure is free of metal. All of the components were glued together.

Interior deck system for the Desiro ML/ÖBB

Following the development of the interior deck system for the Desiro ML Mittelrheinbahn and the Desiro ML Brüssel at TC and its subsequent delivery, the interior deck system for the Desiro ÖBB is now being manufactured at TC. The various systems are based on pultruded profiles made of glass fibre-reinforced plastic produced by Exel Composites in Belgium.

Contract Manufacturing

TC Domine is a dependable partner for the high-precision machining of components made of thermoplastics and glass fibre or carbon fibre-reinforced plastic. Six modern CNC machines with up to five axes can machine components 6,140 mm long, 1,900 mm wide and up to 500 mm high

As such, we are able to design and manufacture the necessary parts in-house. Subsequent processing steps such as gluing, painting and assembling add-on components are an integral part of what we do.