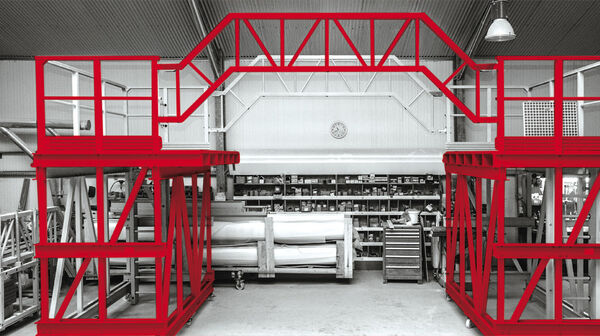

GRP-based design solutions for the chemical industry

Solutions based on fibre composite materials have been successfully used in the chemical industry and plant engineering for many decades. Fibre composite materials are much lighter than metals and do not rust. They are weather-resistant and do not conduct electricity. In addition, they are resistant to many chemicals.

Resistant in corrosive environments

To give one example, steel girders can erode very quickly in chlorine electrolysis systems. Corrosion protection on the required steel girders must be regularly renewed or improved if they are to maintain their load-bearing capacity. This costs time and money.

If, however, structures made of GRP or composites are used in such areas, they will not rust, thus saving a lot of money when it comes to maintaining such systems.

Can be machined and installed without flying sparks

If steel stairways, walkways, handrails and the like need to be adapted on site, flying sparks are inevitable during the grinding process. This is dangerous due to the risk of fire, so the appropriate safety measures need to be observed.

However, if you have installed stairways, walkways, load-bearing structures or handrails made of GRP profiles and then need to adapt them, the process is much safer. Grinding GRP results only in dust that can be vacuumed up, rather than flying sparks. Working with them is thus much safer.

Weather-resistant

Pultrusion profiles made of glass fibre reinforced plastic (GRP), which we use for our special designs, are fitted with a highly resinous surface layer and are thus resistant to weathering. We have set up outdoor walkways and staircases 25 years ago that are still in use today. A little faded, perhaps, but still perfectly stable. A handrail made of glass fibre reinforced plastic will feel significantly warmer than one made of steel, especially at minus temperatures.

Are you facing similar challenges?

Let's talk about possible solutions.